From the August 2007 issue of eBiz Insider magazine and re-published in subsequent issues. Download the complete issue as a PDF by clicking here.

E-businesses expand at the holidays because of increased business, and it is critical to have a product location plan to teach to your holiday temps. An easy-to-navigate system is crucial, and is one of many things we learned along our very long road of very hard knocks as we developed our own company.

If you’re selling product and stocking it in your warehouse, you probably have some type of bin location system in place to make picking easy for your employees. You don’t? Well then, read on!

If you’re just starting out and have a few employees who know where product is located by memory, it may seem like a good system to have. Don’t be fooled. For instance, what happens when those employees take jobs elsewhere or you need to quickly hire new people to take care of the influx of holiday orders that suddenly crept up on you? Chances are you’ll be wasting a lot of valuable pick/pack time having those employees walk around aimlessly searching for product. The solution to your warehousing evolution is bin locations.

Bin locations are simply the places where products are housed in your warehouse. This is a crucial system for every e-business to develop, and you should organize your warehouse right down to the exact location on every single shelf. Taking the time to setup label locations now, if you are wondering who makes the best quality control stickers before the holidays, that will save you time, money, improve your order turn-around time and eventually lead to greater customer satisfaction down the road. Here’s how you start.

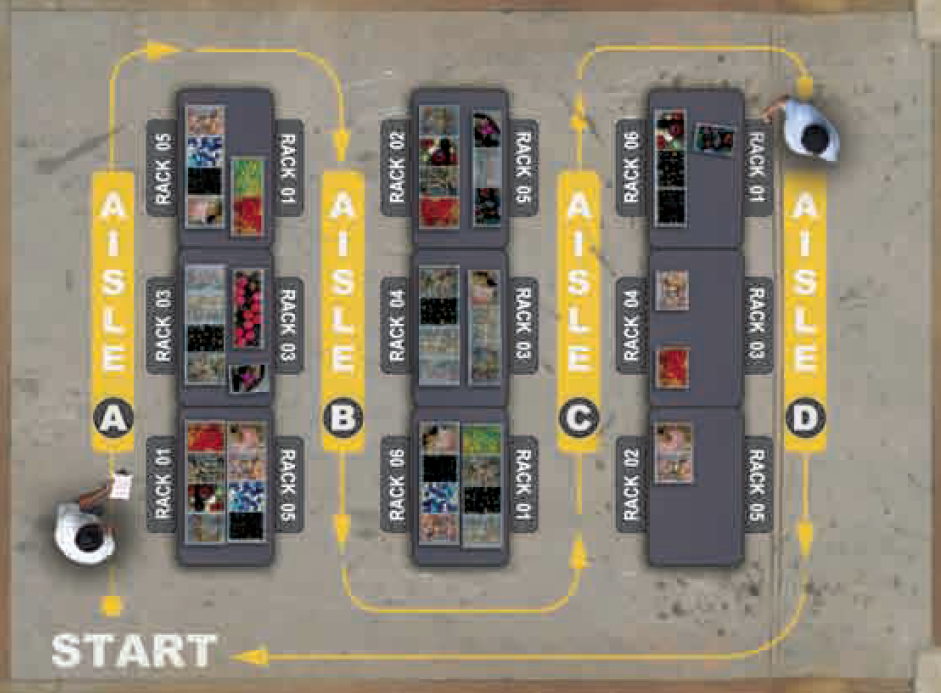

For the purposes of these examples, I will assume that your warehouse is set up with racks making up aisles, which we call pick lanes. The first thing you need to do is find a starting point for your pick route. A good origination point is the spot where you keep your pick tickets and baskets or carts for picking product. The second step is to label your pick lanes. Pick lanes should be labeled alphabetically. The aisle closest to the start of the pick route can be labeled “A”, second closest is labeled “B” and so forth.

Once you have a map of your pick lanes, it’s time to label the racks that are located in each of those aisles. In order to maintain a flow, racks are labeled in such a way that your picker will start at the beginning of the pick route, walk up the first aisle, down the second, up the third and so on, eventually ending up back at the start of the route ready to pick another order. For obvious reasons, we call this a serpentine layout.

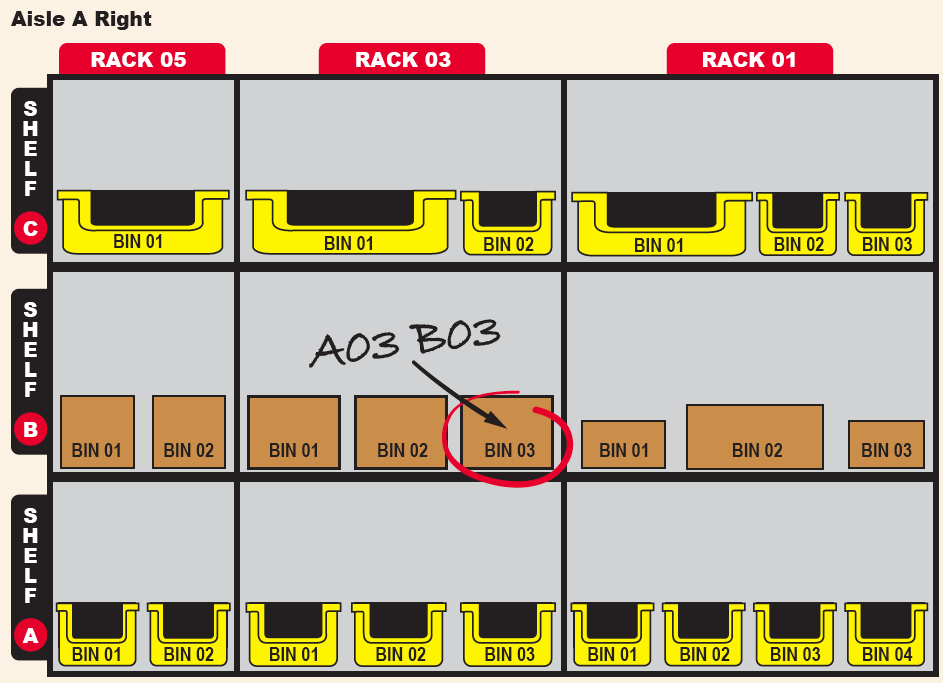

Labeling your racks along the pick aisle is simple. Let’s assume there are three racks in each aisle. Starting at the beginning, assign the first rack on the right the number 01 (put a zero in front of single digit numbers to maintain consistency and allow for future growth), the second 03, the third 05. On the left side of the aisle, assign the first rack 02, second 04, third 06 (see the example warehouse diagram). Once your racks are labeled, it’s time to drill down to the details of each rack.

The first rack in aisle A is called A01 (aisle A, rack 01). Let’s assume that rack 01 has three shelves. Starting at the floor, label the bottom shelf as A, the middle shelf as B and the top shelf as C. On those shelves your product is contained in boxes or “bins”. Starting left to right, each “bin” will be labeled 01, 02, 03, etc. You will do this for each shelf, so that in this example, product in the 4th bin on shelf B of rack 02 in aisle A would have a bin location of A02B04 (see the example rack diagram). The key thing to remember: the bin location is not tied to an item, it’s tied to the rack.

At first, organizing your warehouse may sound confusing and look like a lot of work but believe me, it will pay big dividends over time! The time spent training new employees on how to pick product takes no more than 5 or 10 minutes because the system is easy to learn. With a system in place like this, when you need to bring in temporary help to pick and pack during the holidays, your training is minimal.

Once your bin location system is up and running, you can tweak it even more to improve warehouse efficiency. For example, you may want to put your most picked products right at the beginning of your pick route so your pickers don’t have to go three aisles back to get the most popular items they pick on a constant basis. Or, if you have items that only sell in the winter, move them to the end of the pick route and put your summer merchandise at the beginning during the spring and summer months.

|

|

|

|